Fall is when I work. For most of the summer, the big rollup doors of my shop start ratting about ten, and by noon they are telling me it’s Fukinukin’ in the Gorge, and it’s time to drop the tools and go play. I always do. So not that much gets done. From mid-august on the wind gets a bit lighter and much more flukey. So I spend more time in the shop with my innumerable projects. Taking the first position is the new/old 1990 BMW R100GS sort of Paris Dakar. This is one great bike, and I’m going to make it a lot greater. Right now I’m doing all the reliability mods. I tore apart the transmission, looked at everything, replaced all the bearings and I’m adding the circlip that the factory should NEVER have abandoned.

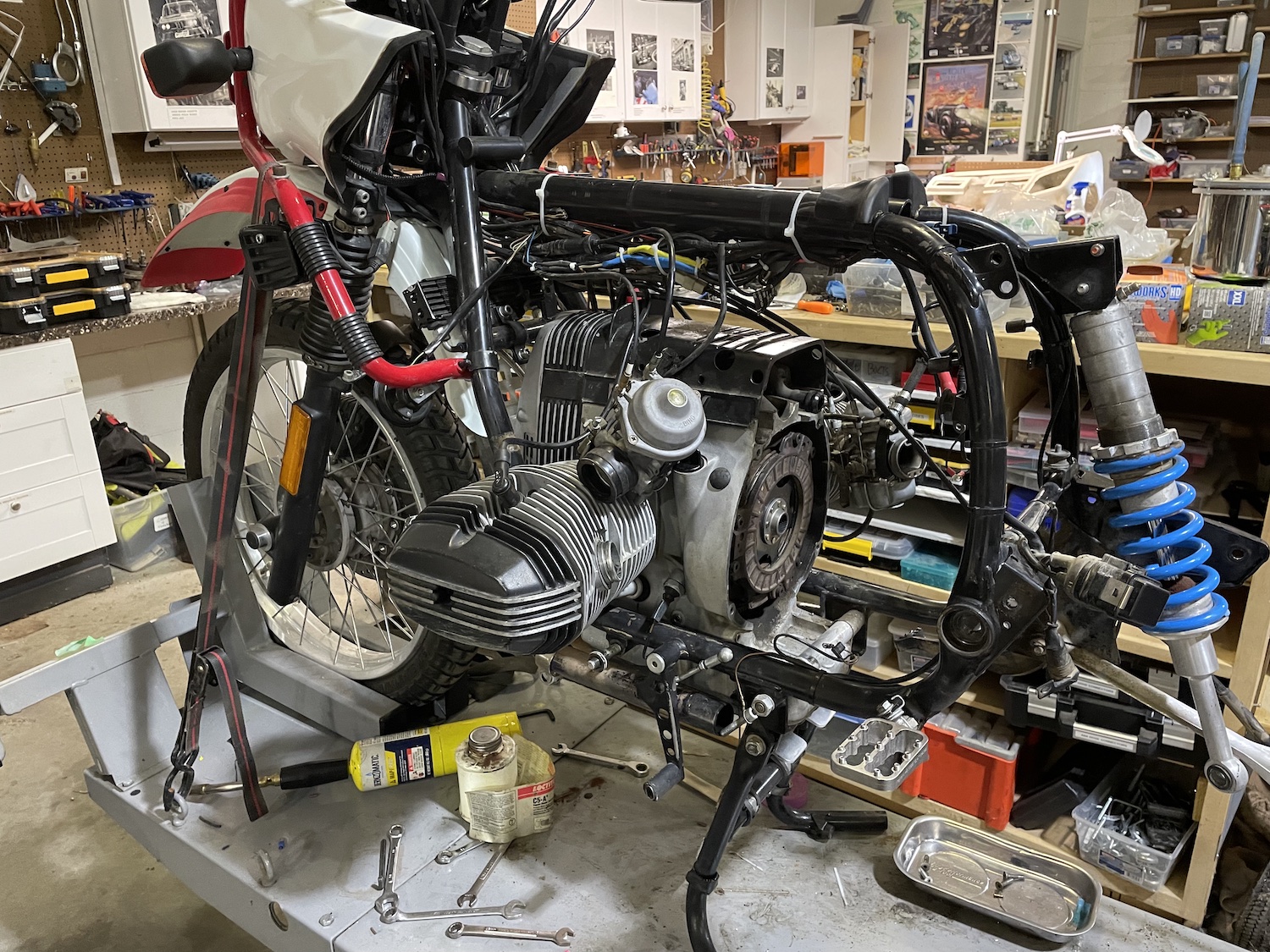

Pretending to be organized. Sort of.

New rebuildable, grease-able driveshaft, a very careful course of shimming to minimize endplay, and then I’ll stick that all back together. In the process, I realized that I need to install my mongo rotary air compressor and high-pressure big ass tank compressor so I can convert my bead blasting cabinet into a vapor blaster. So hey–new project.

In the meantime, I pulled off the subframe on the BMW and took it apart along with the lower crash bars. It’s looking a bit naked.

My plan is to get all this stuff powder-coated bright red, as the works bikes had. It’s gonna look wicked. I could powder coat it myself, I have a setup for doing it, but I don’t have an oven in my shop. I know, WTF is wrong with me? I had an oven in my old shop but just haven’t done it yet. So all this stuff is going to the powder coaters tomorrow. It will be the same color as the ‘roo bar on the nose–I hope. I’m bringing the side cover as a color reference. It’s a bright red with no orange in it. An old housepainter, like me, would call this a blue-red.

This brings me to project #2, an insane shop upgrade. Years ago a friend of mine discovered the big Ingersoll-Rand rotary compressor he’d bought at auction in a weak moment was too big for his shop. He offered it for what he’d paid for it, so I took it. I already have a big ol’ piston-type compressor slowly rotting outside while I get by with a decent portable 5HP compressor. But it’s not handy like an installed shop air system, and it won’t power my blast cabinet. So I’m going to hook up this big 10HP three-phase rotary screw buggah and have distributed air.

The main reason to do this is I want to convert my big blast cabinet to vapor blasting, also called vapor honing. It’s basically glass bead blasting with water, and the big benefit is it doesn’t damage the underlying metal, plastic, glass, whatever–just cleans off all the surface crap. I’m going to clean out all the junk in the open covered area behind my shop where I used to store Nero, my airstream race car hauler. I’ll put the blast cabinet there along with a few other bulky things that are taking up too much shop space. That same area is going to be extended a few feet and I’ll install one of my containers across the end to contain a full battery from a wrecked Tesla model three. Lots of PV on the roof, big-ass battery, various electronic doodads to try to keep the thing from exploding (hence the steel container), inverter, blah, blah and I will generate all my power at the point of use. At least that’s the plan.

It all fits together–sort of. Like most of my plans–makes theoretical sense, now I have to execute.

In the meantime, I redid the laminate on my saw table. It had an irritating bubble in the middle. All better now– I hope. I got the most bicep exercise of the last five months carrying the weights out from the office area. They normally rest there in a stack against the wall, shaming me for never touching them.

In the meantime I

Last but not least, my new flying dutchman wing foil board. this is the bottom. the top is black. Haven’t seen it yet–it’s waiting for me in Maui.